Advantages• More samples per headcount

• More samples per headcount

• Faster turnaround of results

• Improved quality, precision, accuracy and sensitivity

• Consistency of preparation

• Compliance with regulatory requirements

• Improved safety

• Quick response to peak or unexpected work loads

Compatible with 1, 3 and 6 mL SPE Columns Increased bed height enables the use of a wider range of SPE cartridges including all ISOLUTE® and EVOLUTE® bed masses allowing for flexibility in methodology.

Larger sample volumes

Larger sample volumes A new 5 position rack for 40 mL scintillation vials allows for larger sample volumes to be processed, often desired for food and environmental applications.

Delay Start feature Easily leave extracted samples unattended. Samples are freshly prepared when you return.

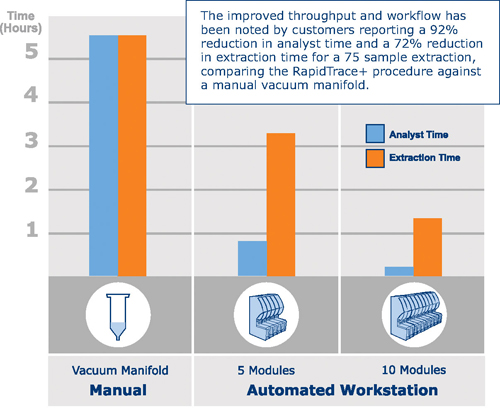

Modular design allows for up to 10 linked units 10 RapidTrace®+ systems can be controlled by a single computer. The Modular design allows users to start with one module and expand up to 10 linked units. Modules within a group can run different methods independently and if one module is shut down for operator attention, other units remain operational so that sample throughput is not halted.

Accelerated methods development and optimization

Accelerated methods development and optimization Utilizing the easy-to-use interface, it is simple to implement a structured, rational strategy for optimum SPE conditions in experiments.

Readily transferable methods Methods stored in the RapidTrace

®+ controller can be instantly recalled and transferred to other units with 100% confidence

Positive Pressure Syringe Displacement Positive pressure displacement allows for accurate processing and improves reproducibility in flow rate sensitive methods.

Safety and Security

Safety and Security Enclosed working parts ensures operator safety and reduced exposure to solvents and hazardous compounds. Additionally, password protected control software limits access to methods ensuring method security. Combined with magnetically encoded racks, run initiation is simplified and the possibility of loading an incorrect procedure is reduced.

8 Solvent Inlet Lines Allows for more flexible use of solvents and provides an excellent system for method development.

Segregated Waste Lines Three segregated waste lines allows for separate aqueous, organic and biological waste disposal to simplify hazardous waste handling and reduce disposal costs.

Simple and Reliable Simple, rugged design with a minimum of moving parts and easily accessible consumables allows for a robust system with minimum “down-time”.

Fast and Easy Method Development with Easy-to-Use Software Utilizing the familiar Microsoft® Windows® interface, operators can easily implement a structured, rational strategy for method-development to determine optimum processing conditions for each sample. The methods can be written in minutes and recalled in seconds. Optimization of processing conditions is possible in a fraction of the time compared with conventional manual techniques. Column formats, reagents, concentrations and flow rates can be thoroughly explored as the system allows for incremental manipulation of any parameter (eg. pH, solvent concentration, cartridge type, flow rate etc)in order to determine effects on recovery and precision. Operators can insert, delete or manipulate steps and easily adjust parameters.

Methods can be assigned to an individual sample or by module. The methods stored in the RapidTrace+ controller can be easily transferred to other RapidTrace+ workstations. Additionally, methods can be saved and run concurrently or true, unattended, “multi-method” sample processing. This unique and rational method design capability dramatically speeds the development of rugged and reliable methods.

Compliance Validation The RapidTrace+ Start-up Kit and Software, includes a Validation Manual that allows operators to walk through the validation process of their RapidTrace. This ensures that RapidTrace®+ provides the consistently clean extracts required for today’s sophisticated analytical instruments and regulatory bodies. The Validation Plan defines the methods and documentation utilized in the development, execution and reporting of a validation for a RapidTrace Workstation. It addresses Installation, Operation, and Performance Qualification. This comprehensive document enables operators to meet GLP, GMP and GOP requirements.

Magnetically Encoded Racks Magnetically Encoded Racks enable the user to designate a specific method to a rack. When using magnetically encoded racks, the method does not have to be initiated via the controller software, because the module reads the magnets and automatically knows which method to run. The module runs the number of samples corresponding to the number of sample test tubes placed in the rack. This means that software control of the system can be bypassed and methods will not be altered during routine operation. Labs around the world find this useful in production mode.