| TurboVap 500 Automated Evaporation System |

Sensor Endpoint Detection

Closed Cell Concentrator

No Gas needed

Solvent Vapor Recovery

|

Advantages

√ Patented Vortex Shearing Technology

√ Patented Sensor Endpoint Detection - no monitoring required

√ Operators are freed to perform other tasks, further improving lab productivity

√ No “bumping” means no re-working of samples, saving you money every week

√ Solvent vapor recovery system - laboratory emissions can be greatly reduced

√ User-friendly displays and diagnostics

√ Convenient bench top size - no hood space required

√ No need for fume hood

√ Portable - No Gas required applications

Environmental samples

√ Agrochemical samples

√ Forensic and crime samples

√ Drugs of abuse samples

√ Food and beverage analysis

√ Pharmaceutical biotech compounds

√ Clinical samples

√ Remote locations | Ordering Information

| Part Number |

Description |

Qty |

| Biotage TurboVap® 500 : 본체 (Evaporation Tube, 보조랙 포함) |

| C103203 |

TurboVap 500, 200/220V, 50/60Hz |

1 |

| |

| Evaporation Tube : 추가구매 품목 |

| C128510 |

Evaporation Tube, 500 mL, 0.5 mL Endpoint, 2/pk |

1 pk |

| C128515 |

Evaporation Tube, 500 mL, 1 mL Endpoint, 2/pk |

1 pk |

| C128514 |

Evaporation Tube, 500 mL, Flat Bottom, 2/pk |

1 cs |

| |

| Accessories |

| C45400 |

Auxiliary Rack (500ml, 2 positions) for TurboVap 500 |

1 |

| C45412 |

Glass Cover : 500 mL sample tube용, 2/pk |

1 pk |

| |

| 필수 준비 품목 : 필수 준비 품목 |

| • Condenser coolant supply 또는 찬 수도물 |

| |

| Technical Specs |

| Number of samples |

2 |

| Water bath remperature |

Ambient to 95 °C. (Upper temperature with sensors is 60°C) |

| Timer range |

1–99 minutes |

| Power requirements |

110/120 VAC at 60 Hz (European, 230 VAC at 50 Hz) 900 VA max |

| Net weight |

42 lbs. (18.6 kg) |

| Shipping weight |

60 lbs. (27.2 kg) |

| Dimensions |

21.2” x 24” x 11.9” |

| Maximum sample volume |

500 mL |

| Evaporation rate |

Adjustable based on water bath temperature, fan speed and chille |

| Final endpoint volumes |

Selectable. Automatic endpoints of 0.5 mL and 1.0 mL or dryness. |

| Solvent reclamation |

95% of solvent vapors under typical conditions |

| Technology |

Gas vortex shearing technology |

| Gas supply requirements |

Internal fan, 4000~8000 rpm, No external gas required |

| Exhaust |

– |

| Minimum operating pressure |

No gas required |

| Certifications |

2006/95/EC Low Voltage Directive 2004/108/EC EMC Directive 93/68 |

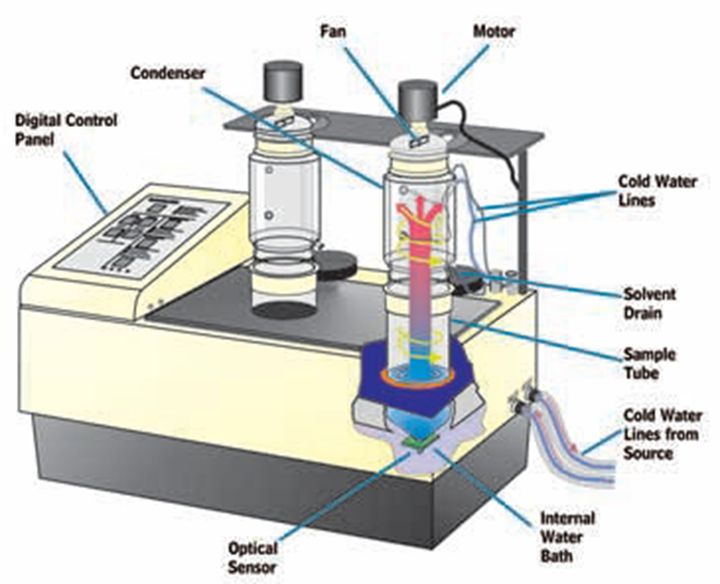

TurboVap® 500 Concentration Evaporator Workstation is a closed cell evaporation system that provides automated sample concentration and solvent recovery using a helical gas flow and sensor endpoint detection technology.

TurboVap® 500 can evaporate volumes up to 500 mL down to complete dryness with flat bottomed vessels or to a selectable endpoint at 0.5 or 1 mL. A water bath is used to maintain stable temperature, while the cooled glassware condenser collects the solvent. The condenser technology allows for efficient and cost effective collection of hazardous waste. It also prevents losses of samples and allows for analysis to detect cross-contamination issues.

The “helical flow” of air is created by a motor-driven fan. The solvent vapors rise and enter the condenser, condense on the side walls, then run out the drain into a suitable waste or reclamation container. The two position unit accommodates 500 mL vessels with either 0.5 mL or 1.0 mL endpoint stems. Biotage delivers the most efficient and rapid solvent evaporation systems for chemistry laboratories around the world.

Applications

In environmental laboratories, concentration of large samples is often a time consuming process. TurboVap 500 efficiently concentrates organic solvent extracts to 0.5 or 1.0 mL and sounds an alarm when finished. This "load and leave" capability frees the analyst for more important work.

TurboVap® 500 is also an excellent alternative to traditional rotary evaporators used in organic synthesis. With a 500 mL solvent capacity and water bath temperatures up to 95 ºC, synthesis mixtures are processed quickly. The unique vortexing action maintains the components of interest in the solvent during evaporations and minimizes the “plating” of the compounds on the vessel walls. The open top cylindrical design of the sample tube, with a small stem at the bottom, provides an easy way to recover the products of interest when the evaporation is completed.

|