Drip Flow Biofilm Reactor®

Unlock the Potential of the Drip Flow Biofilm Reactor® for Your Research and Development Needs

The Drip Flow Biofilm Reactor® is a versatile system designed for various research applications. It consists of four (4) or six (6) parallel test channels, each capable of holding one (1) standard glass microscope slide-sized coupon or a length of catheter or stint (after custom modification upon request).

Efficient, Precise Design, and Reusability

Growth media is provided by dripping over the coupon or catheter surface, creating low shear conditions and a short residence time (2 minutes). For catheter and stint studies, an alternate end media port allows flow within the catheter or stint. Media flows via gravity to ensure a very low shear condition. The Drip Flow Biofilm Reactor® is designed for ease of use and reusability. It can be conveniently autoclaved and reused, ensuring consistent, high-quality testing throughout your research journey.

Experience the difference and accelerate your path to innovation and discovery with the Drip Flow Biofilm Reactor®.

4-channel PET (polyethylene terephthalate) Drip Flow Biofilm Reactor® with Reactor Support Stands

6-channel polysulfone Drip Flow Biofilm Reactor® with Reactor Support Stands

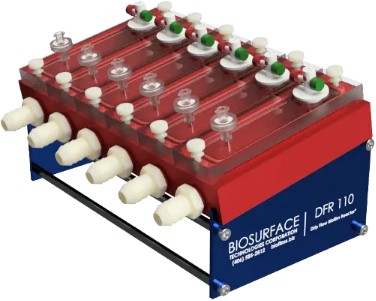

6-channel red-anodized aluminum Drip Flow Biofilm Reactor® with Reactor Support Stands

DFR Material SelectionPolysulfone is the original yellowish-clear plastic. It is autoclavable and resistant to acidic chemistries, but very fragile (crystalline plastic that easily cracks or crazes). Black Polyethylene Terephthalate (PET) has similar chemical resistance as Polysulfone but is much more resistant to physical and thermal stress (amorphous plastic without fracture planes). It is also a slightly less expensive option. PET is an opaque autoclavable thermoplastic. Both plastic options will eventually decay from repeated autoclave cycles. Anodized Aluminum is very resistant to thermal and physical stress. The anodized coating is very thin and can be scratched easily. Once the anodized coating is removed, the underlying aluminum metal is very reactive in salt-containing solutions (growth media). The anodized coating will decay after repeated exposure to acidic conditions. The coating can be reapplied by reanodizing.

ASTM Standard Method using the Drip Flow Biofilm ReactorStandard Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown Using Drip Flow Biofilm Reactor® with Low Shear and Continuous Flow:

ASTM E2647

|